Pasar al contenido principal

- Professional mobile support table

- ILAC / equivalent authority Certificate

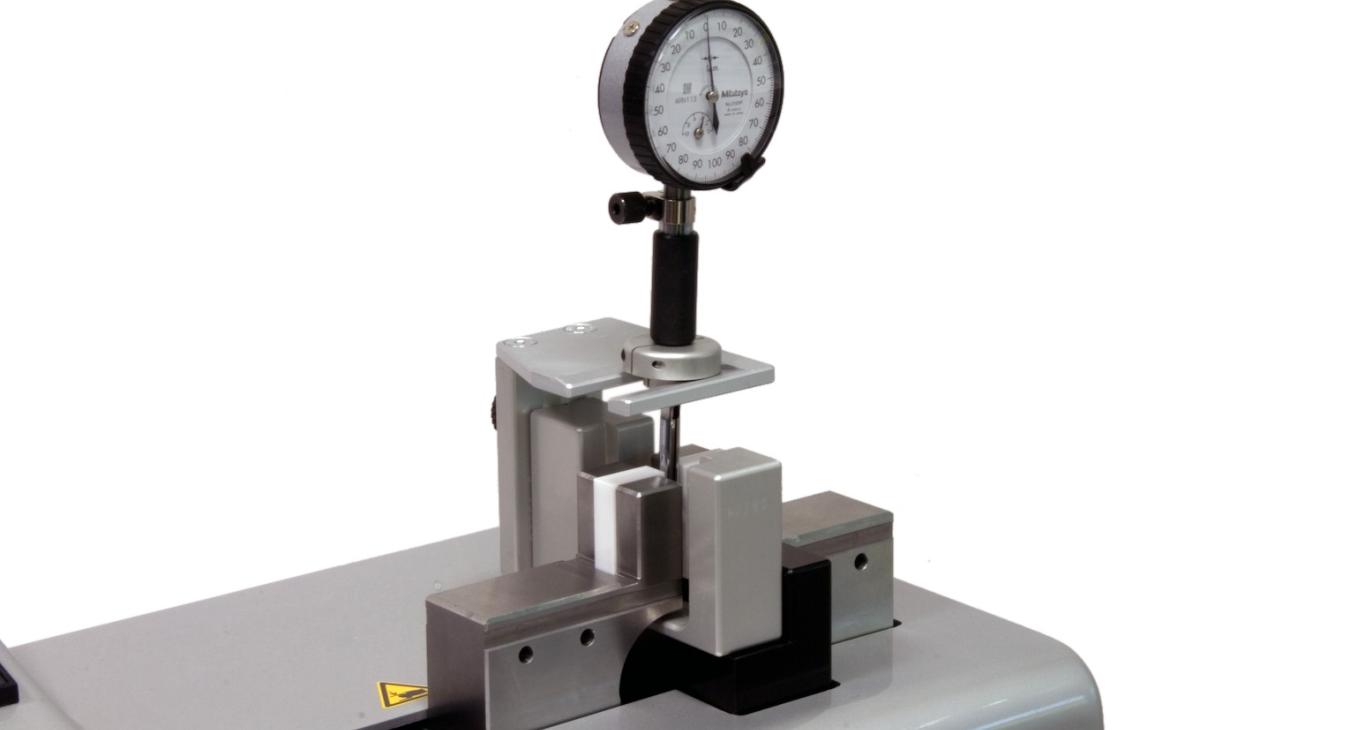

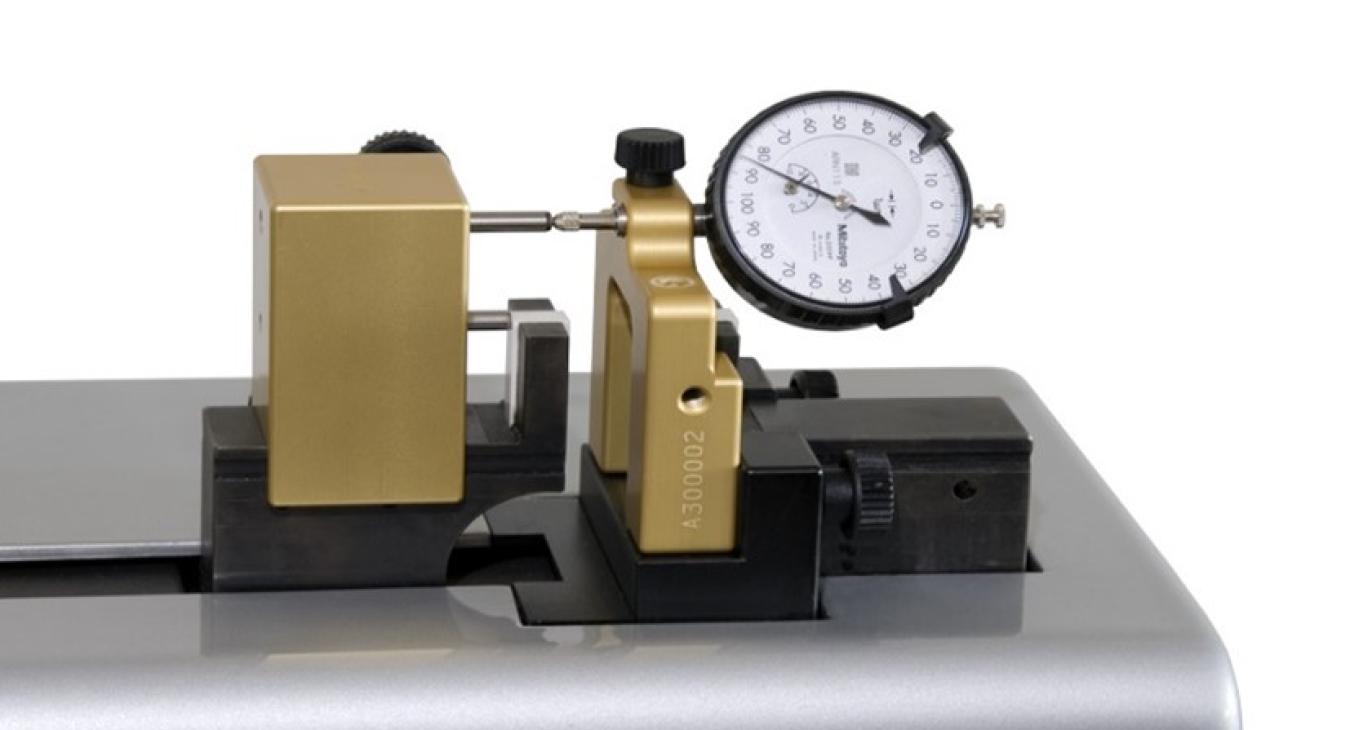

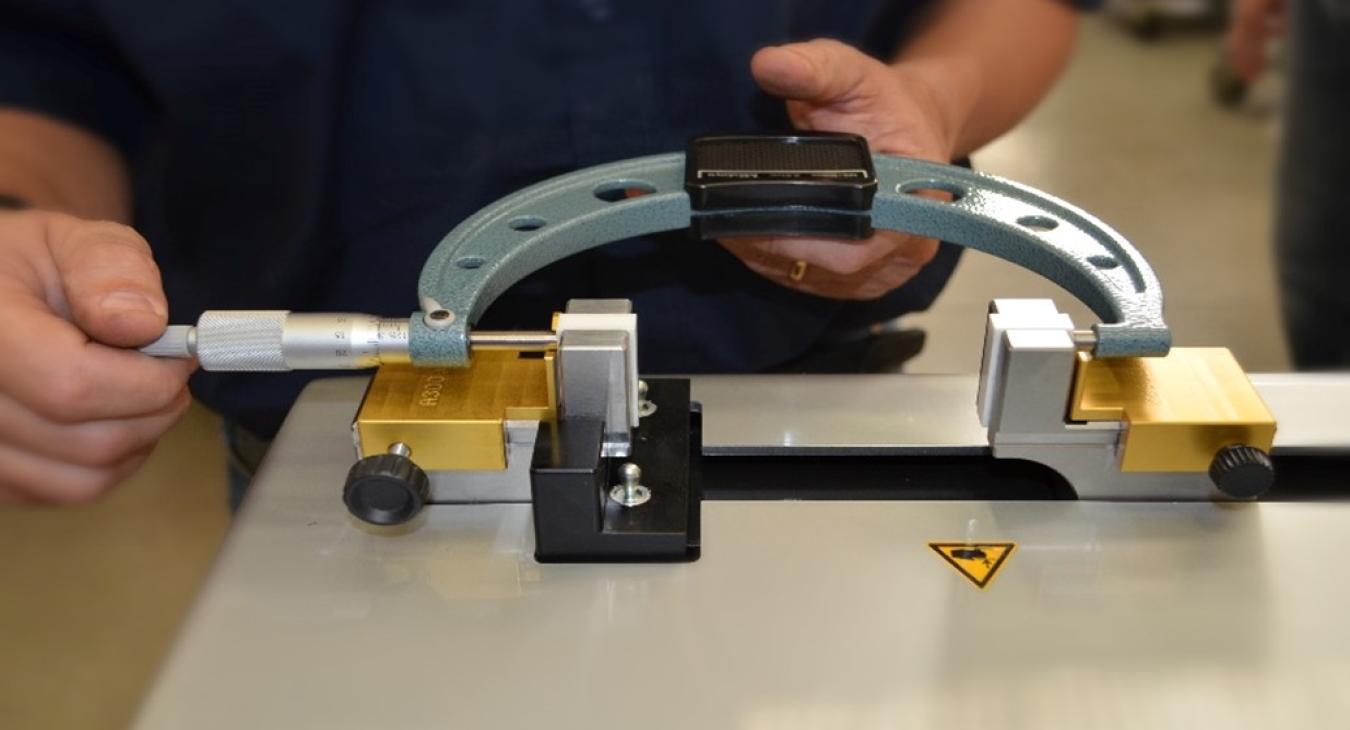

- Couple of anvils in hard steel

- Bar code scanner for value recall

- Reduction of the zeroing and presetting operations.

- Cost saving, in terms of non-purchasing master rings and gage blocks: TR can replace , Micron per Micron, any master ring plus all gage blocks.

- Better accuracy in presetting: the operation with the gage blocks requires precision and time: with TR you just have to digit the value.

- With TR it’s easier: in any zeroing operation you have one fixed point and the chance to have 2 hands free to reach the minimum point. The operator error is reduced.

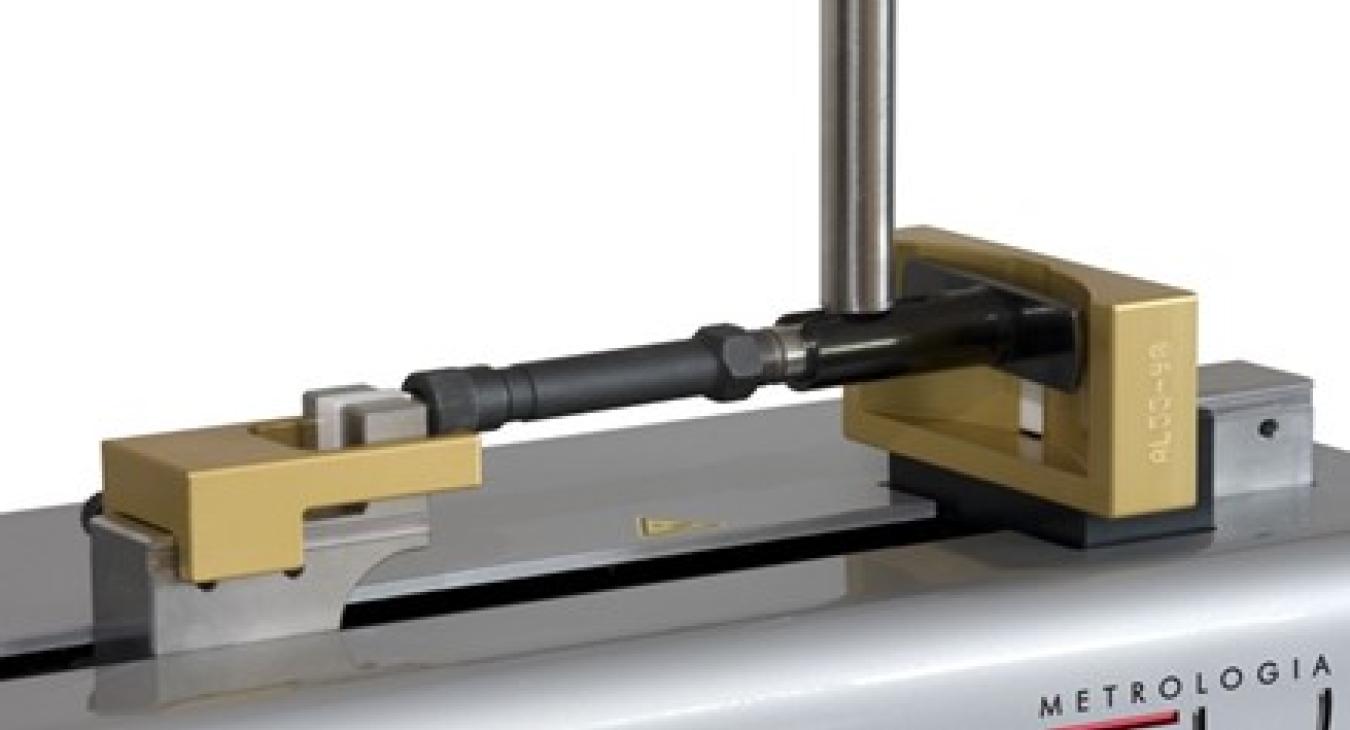

- With patented adapters that guide the instruments during the operations, the TR can work on the internal and the external of the ceramic blocks.

- The hardness of the ceramic ensure durability.

- If certified by a recognized authority, TR can be a certified Primary Reference which allows the company to the Inhouse calibration of the instruments and consequently represents a cost saving option and ensures the permanent availability of the instruments in the workshop.

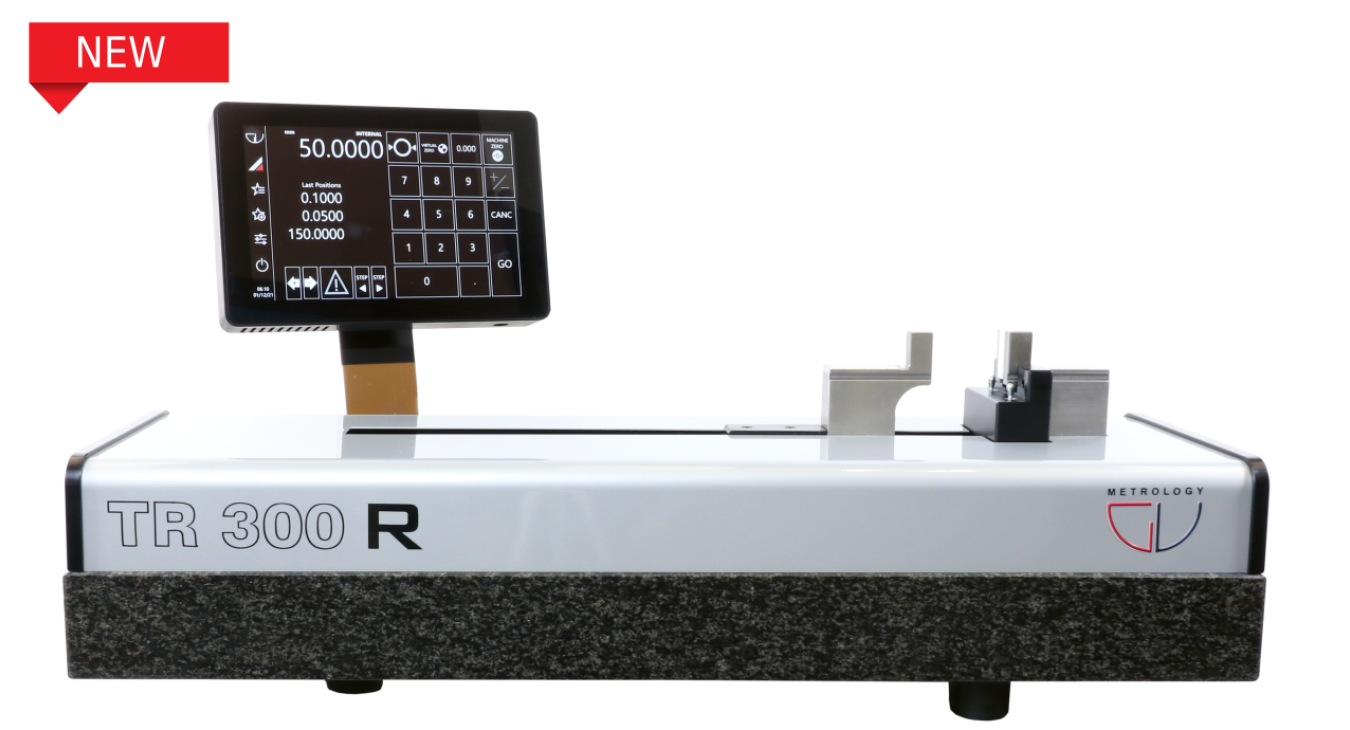

- Bar code scanner for value recall

- Alphanumeric keyboard

- LCD Display with 20 characters

- Stores up to 100 positions ( OD + ID )

- SW interface with remote PC / Printer

- Connectivity and Storage via USB

- Professional mobile support table

- ILAC / equivalent authority Certificate

- Couple of anvils in hard steel

- Bar code scanner for value recall

- Reduction of the zeroing and presetting operations.

- Cost saving, in terms of non-purchasing master rings and gage blocks: TR can replace , Micron per Micron, any master ring plus all gage blocks.

- Better accuracy in presetting: the operation with the gage blocks requires precision and time: with TR you just have to digit the value.

- With TR it’s easier: in any zeroing operation you have one fixed point and the chance to have 2 hands free to reach the minimum point. The operator error is reduced.

- With patented adapters that guide the instruments during the operations, the TR can work on the internal and the external of the ceramic blocks.

- The hardness of the ceramic ensure durability.

- If certified by a recognized authority, TR can be a certified Primary Reference which allows the company to the Inhouse calibration of the instruments and consequently represents a cost saving option and ensures the permanent availability of the instruments in the workshop.

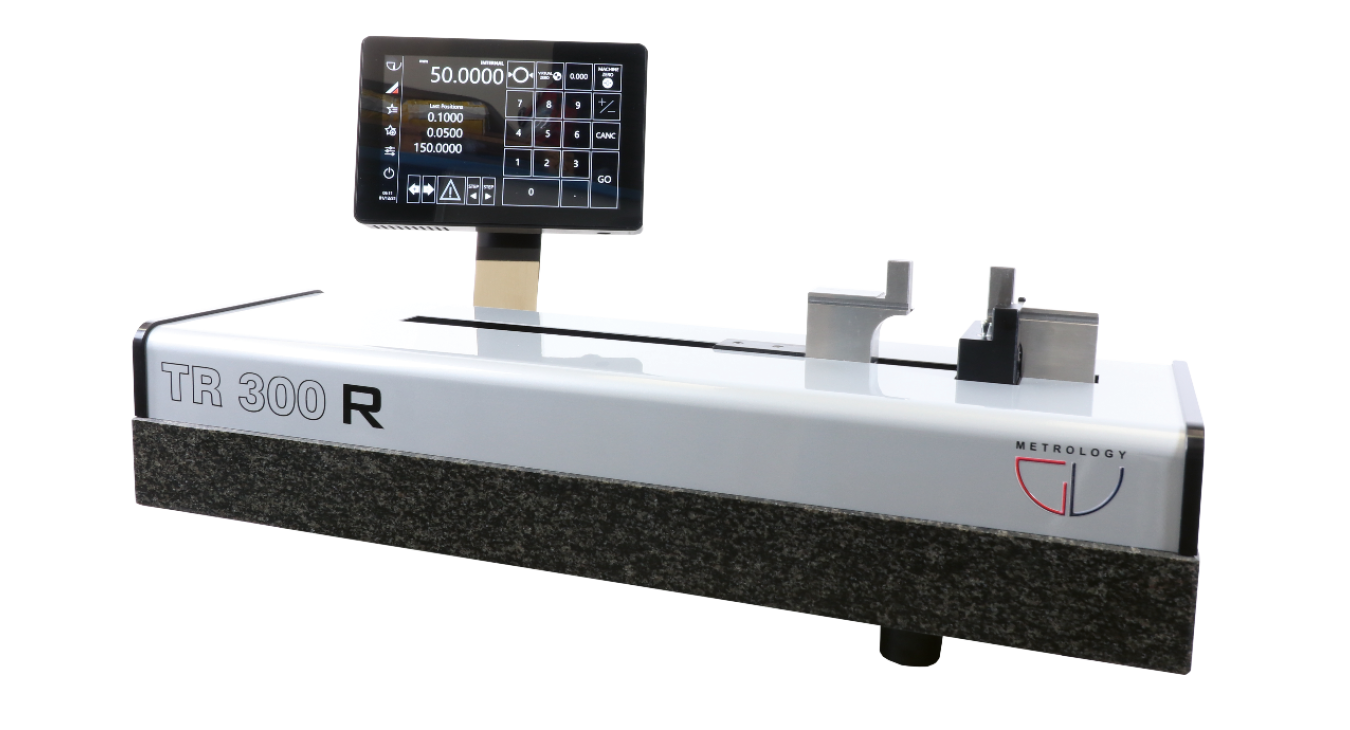

- Bar code scanner for value recall

- Alphanumeric keyboard

- LCD Display with 20 characters

- Stores up to 100 positions ( OD + ID )

- SW interface with remote PC / Printer

- Connectivity and Storage via USB

| TR SERIE R | | 300 | 600 | 1000 | 1500 | 2000 | 3000 | 4000 | 5000 |

|---|

| Measuring range ID | mm (in) | 300 (12) | 600 (23) | 1000 (40) | 1500 (60) | 2000 (80) | 3000 (120) | 4000 (160) | 5000 (200) |

| Measuring range OD | mm | 340 | 640 | 1040 | 1540 | 2040 | 3040 | 4040 | 5040 |

| Weight | Kg | 75 | 100 | 180 | 320 | 400 | 500 | 750 | 930 |

| Interface | | ETHERNET/USB |

| Max Permissible Error | µm | 3 µm + L /300 |

| Repeatability | µm | 1 |

| Resolution | µm | 1 |

| Working temperature | °C | 10 – 35 |

| TR SERIE S | | 300 | 600 | 1000 | 1500 | 2000 | 3000 | 4000 | 5000 |

|---|

| Max Permissible Error | µm | 1,5 µm + L /500 |

| Repeatability | µm | 0,8 |

| Resolution | µm | 0,5 |

| Working temperature | °C | 10 – 35 |

| TR SERIE P | | 300 | 600 | 1000 |

|---|

| Max Permissible Error | µm | 1 µm + L /500 | |

| Repeatability | µm | 0,5< | |

| Resolution | µm | 0,1 | |

| Working temperature | °C | 20 ± 1 | |