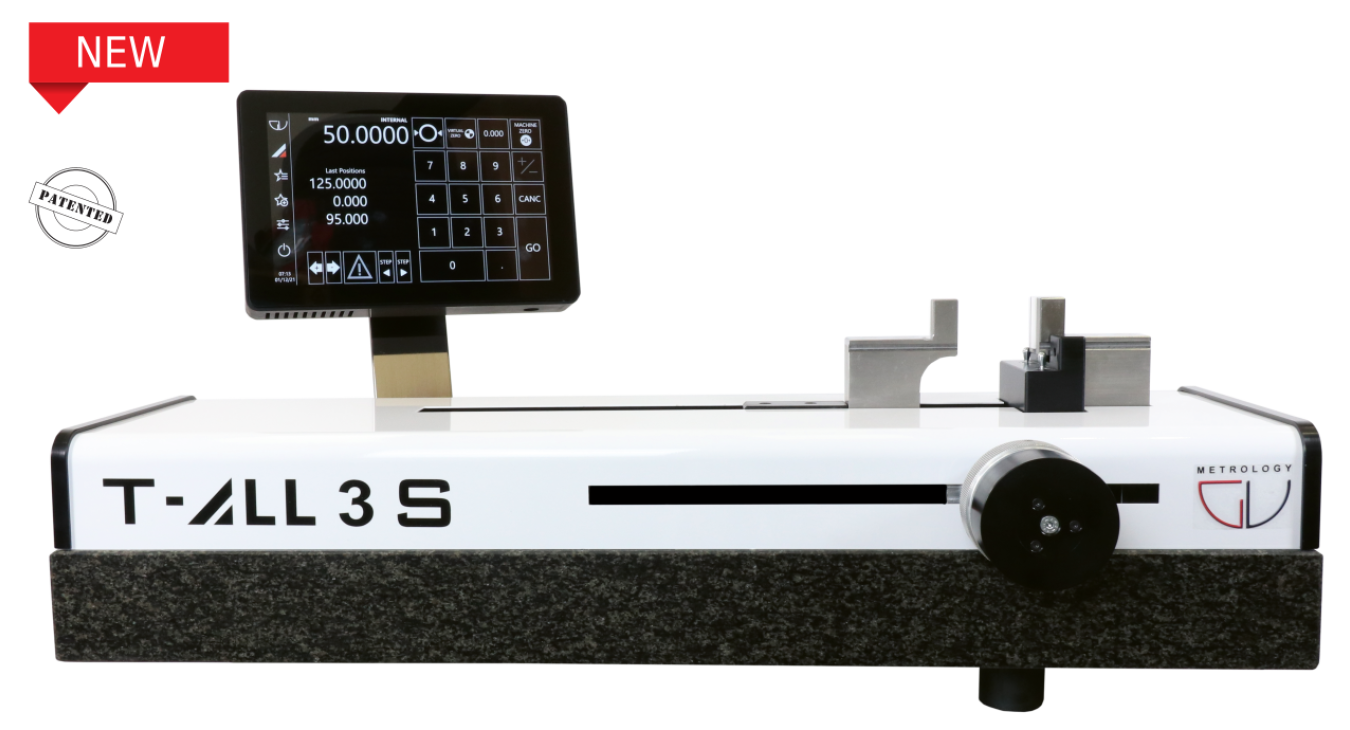

The new bench for setting and calibration instruments with additional measuring function - Patent pending -

T-ALL is the upgrade of the TAR-AL setting and calibration bench integrating the new patended measuring function.

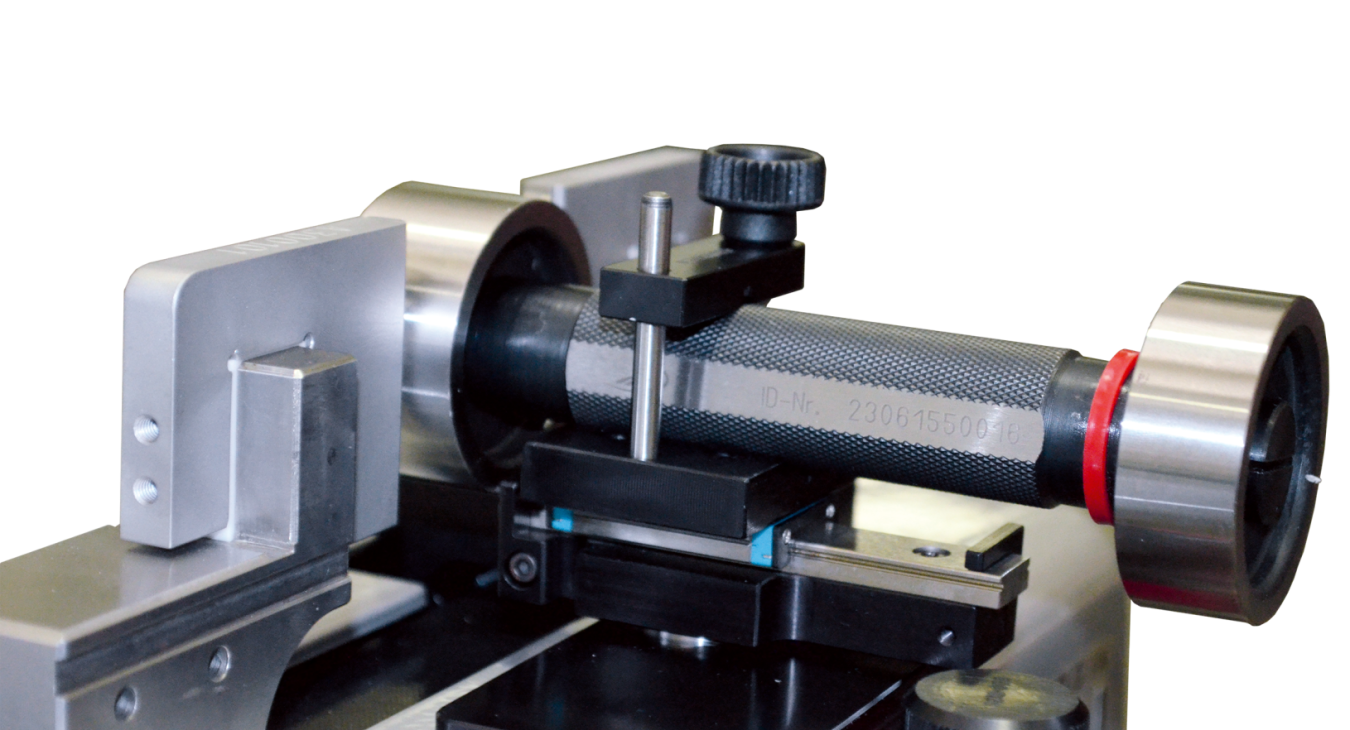

The preloaded handle performs measurements througout manual use.

Measurement of production samples, manual instruments and masters.

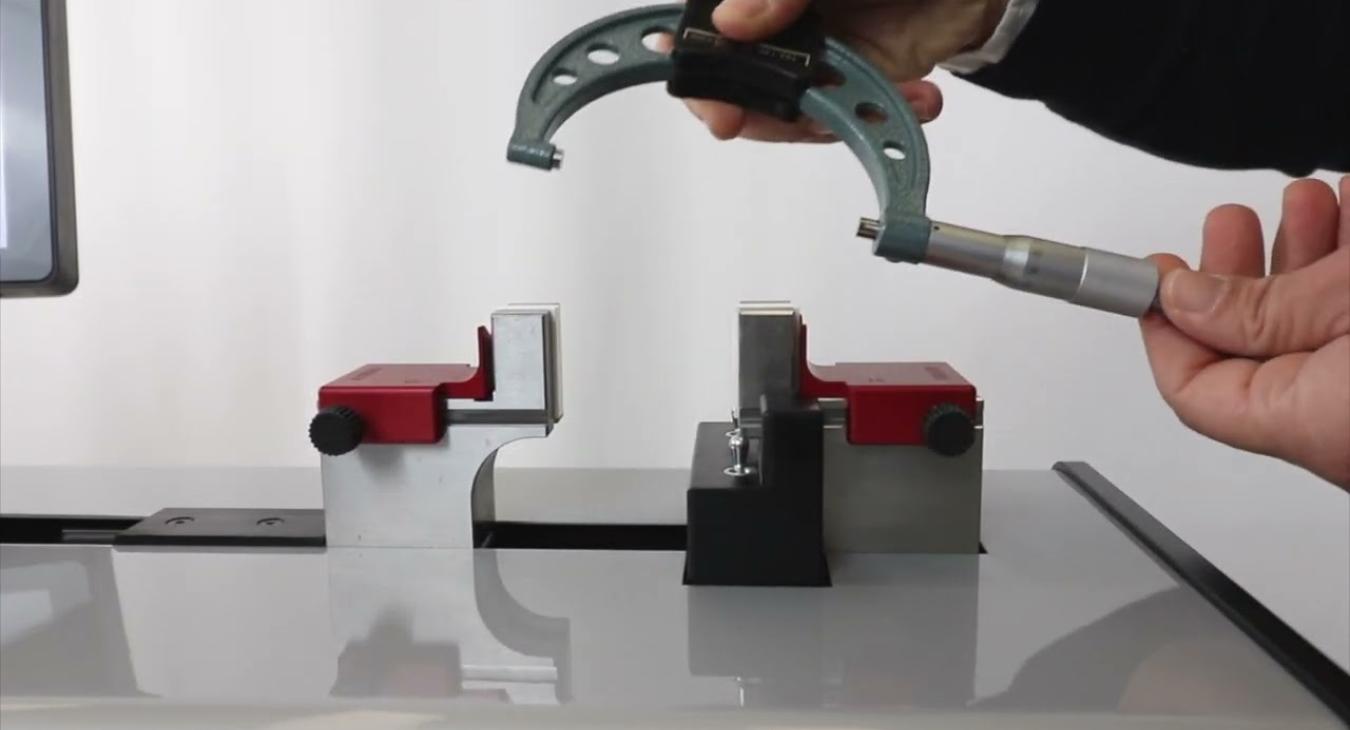

Suitable for setting internal and external measuring tools, such as:

- Two-point bore gauges

- External micrometers

- Vernier calipers

- Digital internal quick calipers

Universal measuring instruments

- Professional mobile support table

- ILAC / equivalent authority Certificate

- Couple of anvils in hard steel

- Bar code scanner for value recall

- Reduction of the zeroing and presetting operations.

- Cost saving, in terms of non-purchasing master rings and gage blocks: TR can replace , Micron per Micron, any master ring plus all gage blocks.

- Better accuracy in presetting: the operation with the gage blocks requires precision and time: with TR you just have to digit the value.

- With TR it’s easier: in any zeroing operation you have one fixed point and the chance to have 2 hands free to reach the minimum point. The operator error is reduced.

- With patented adapters that guide the instruments during the operations, the TR can work on the internal and the external of the ceramic blocks.

- The hardness of the ceramic ensure durability.

- If certified by a recognized authority, TR can be a certified Primary Reference which allows the company to the Inhouse calibration of the instruments and consequently represents a cost saving option and ensures the permanent availability of the instruments in the workshop.

- Bar code scanner for value recall

- Alphanumeric keyboard

- LCD Display with 20 characters

- Stores up to 100 positions ( OD + ID )

- SW interface with remote PC / Printer

- Connectivity and Storage via USB

- Professional mobile support table

- ILAC / equivalent authority Certificate

- Couple of anvils in hard steel

- Bar code scanner for value recall

- Reduction of the zeroing and presetting operations.

- Cost saving, in terms of non-purchasing master rings and gage blocks: TR can replace , Micron per Micron, any master ring plus all gage blocks.

- Better accuracy in presetting: the operation with the gage blocks requires precision and time: with TR you just have to digit the value.

- With TR it’s easier: in any zeroing operation you have one fixed point and the chance to have 2 hands free to reach the minimum point. The operator error is reduced.

- With patented adapters that guide the instruments during the operations, the TR can work on the internal and the external of the ceramic blocks.

- The hardness of the ceramic ensure durability.

- If certified by a recognized authority, TR can be a certified Primary Reference which allows the company to the Inhouse calibration of the instruments and consequently represents a cost saving option and ensures the permanent availability of the instruments in the workshop.

- Bar code scanner for value recall

- Alphanumeric keyboard

- LCD Display with 20 characters

- Stores up to 100 positions ( OD + ID )

- SW interface with remote PC / Printer

- Connectivity and Storage via USB

- Inicie sesión para enviar comentarios

| T-ALL SERIE R | 3 | 6 | 10 | 15 | 20 | 30 | |

|---|---|---|---|---|---|---|---|

| Measuring range ID | mm | 260 | 560 | 960 | 1500 | 2000 | 3000 |

| Measuring range OD | mm | 300 | 600 | 1000 | 1540 | 2040 | 3040 |

| Weight | Kg | 75 | 100 | 180 | 450 | 650 | 1500 |

| Interface | ETHERNET/USB | ||||||

| Max Permissible Error | µm | 3 µm + L /300 | |||||

| Repeatability | µm | 1 | |||||

| Resolution | µm | 1 | |||||

| Working temperature | °C | 10 – 35 | |||||

| T-ALL SERIE S | 3 | 6 | 10 | 15 | 20 | 30 | |

|---|---|---|---|---|---|---|---|

| Max Permissible Error | µm | 1,5 µm + L /500 | |||||

| Repeatability | µm | 0,8 | |||||

| Resolution | µm | 0,5 | |||||

| Working temperature | °C | 10 – 35 | |||||

| T-ALL SERIE P | 3 | 6 | 10 | |

|---|---|---|---|---|

| Max Permissible Error | µm | 1 µm + L /500 | ||

| Repeatability | µm | 0,5< | ||

| Resolution | µm | 0,1 | ||

| Working temperature | °C | 20 ± 1 | ||