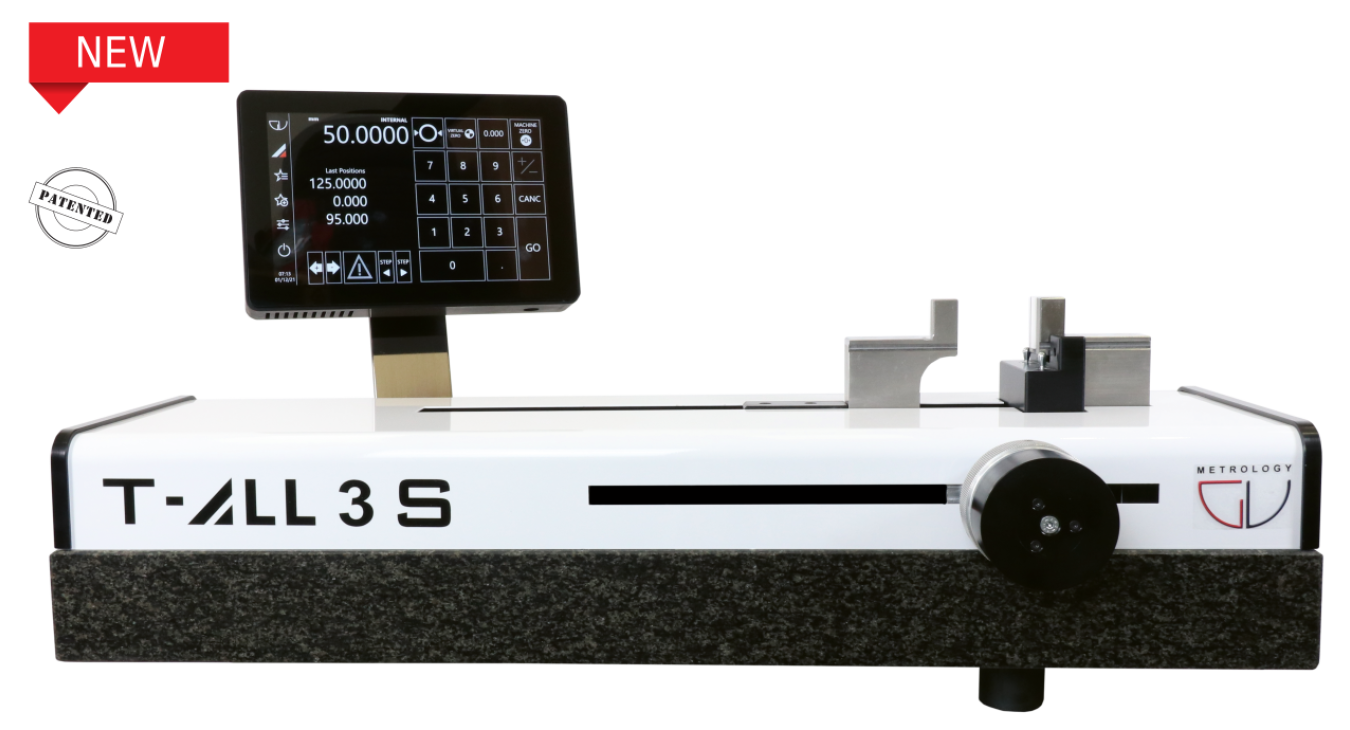

The new bench for setting and calibration instruments with additional measuring function - Patent pending -

T-ALL is the upgrade of the TR setting and calibration bench integrating the new patended measuring function.

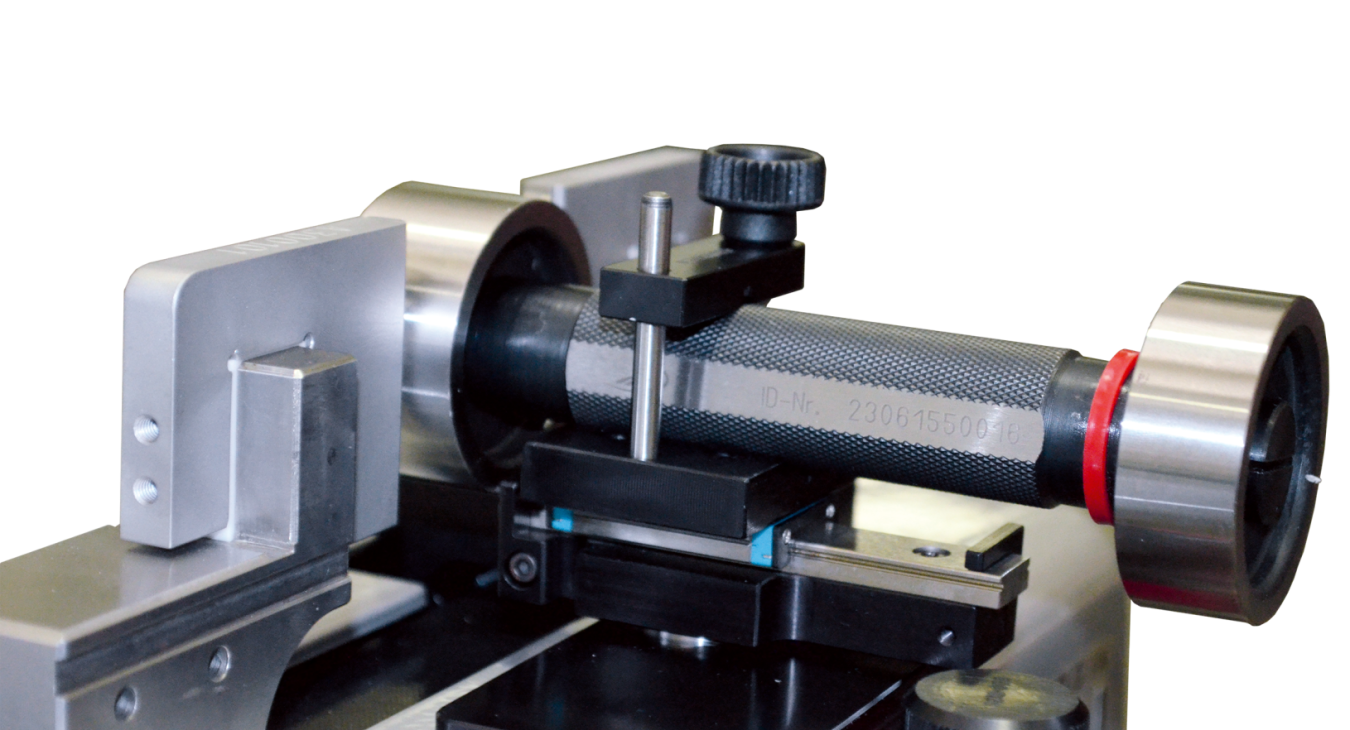

The preloaded handle performs measurements througout manual use.

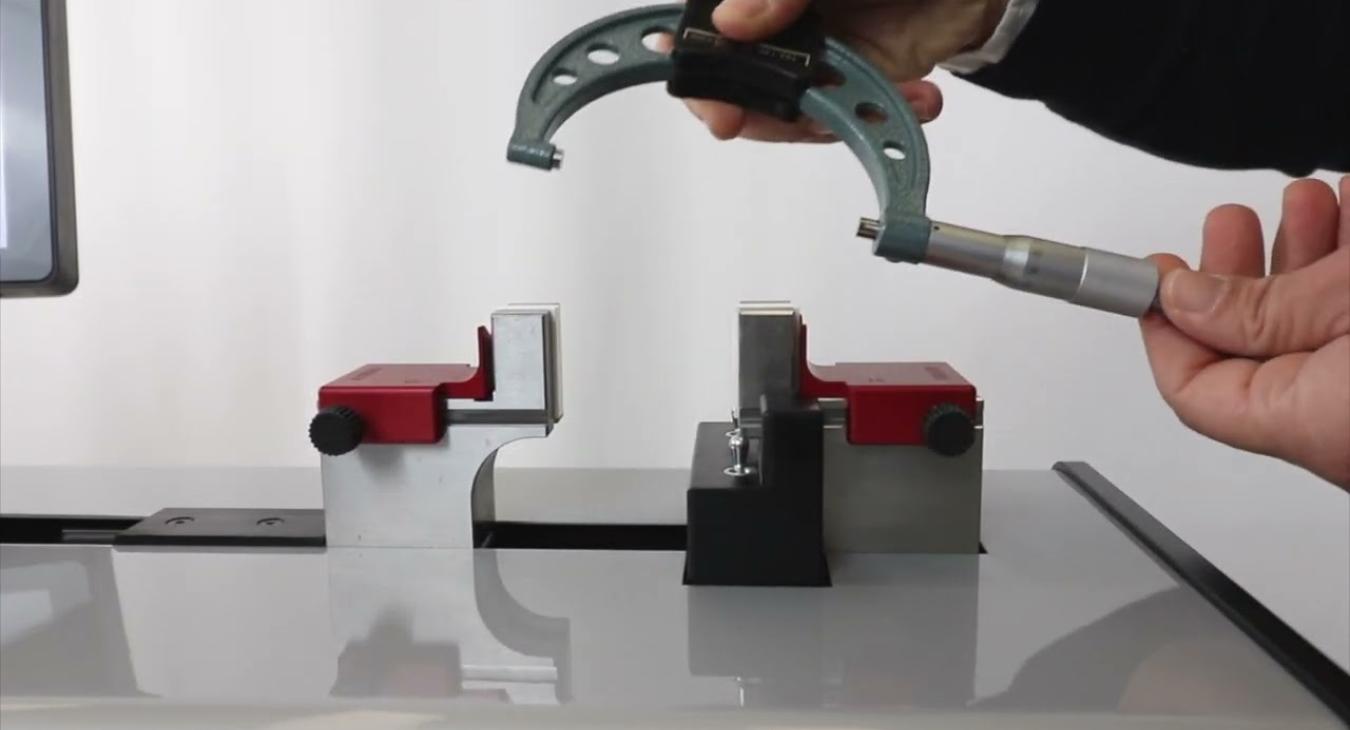

Measurement of production samples, manual instruments and masters.

Suitable for setting internal and external measuring tools, such as:

- 1 performs all functions of the TR model, plus

- Manual measuring mode with constant force

- Calibration of go/no-go plugs, thread plugs up to 85 mm of diameter

- Measurement of max point and min point with dynamic measurement

- Floating professional plate for plugs

- Adjustable plate for measurement of gage blocks

- Hard steel anvils with flat or spheric radius

- Professional mobile support table

- ILAC / equivalent authority Certificate

- Couple of anvils in hard steel

- Bar code scanner for value recall

- Adactive supports for positioning large instruments

T-ALL performs all fuctions of the TR plus:

A precise and fast measurement with unit placed in shopfloor

A check and calibration of gage blocks and plugs – plain and thread ones

Objective measurement due to hardsteel anvils

- Connectivity to PC via ethernet

- Storage of performed data

- 10 inch touchscreen

- Barcode scanner for recalling positions

- Material/temperature position adaptation

- Floating professional plate for plugs

- Adjustable plate for measurement of gage blocks

- Hard steel anvils with flat or spheric radius

- Professional mobile support table

- ILAC / equivalent authority Certificate

- Couple of anvils in hard steel

- Bar code scanner for value recall

- Adactive supports for positioning large instruments

T-ALL performs all fuctions of the TR plus:

A precise and fast measurement with unit placed in shopfloor

A check and calibration of gage blocks and plugs – plain and thread ones

Objective measurement due to hardsteel anvils

- Connectivity to PC via ethernet

- Storage of performed data

- 10 inch touchscreen

- Barcode scanner for recalling positions

- Material/temperature position adaptation

- Log in to post comments

| T-ALL SERIE R | 3 | 6 | 10 | 15 | 20 | 30 | |

|---|---|---|---|---|---|---|---|

| Measuring range ID | mm | 260 | 560 | 960 | 1500 | 2000 | 3000 |

| Measuring range OD | mm | 300 | 600 | 1000 | 1540 | 2040 | 3040 |

| Weight | Kg | 75 | 100 | 180 | 450 | 650 | 1500 |

| Interface | ETHERNET/USB | ||||||

| Max Permissible Error | µm | 3 µm + L /300 | |||||

| Repeatability | µm | 1 | |||||

| Resolution | µm | 1 | |||||

| Working temperature | °C | 10 – 35 | |||||

| T-ALL SERIE S | 3 | 6 | 10 | 15 | 20 | 30 | |

|---|---|---|---|---|---|---|---|

| Max Permissible Error | µm | 1,5 µm + L /500 | |||||

| Repeatability | µm | 0,8 | |||||

| Resolution | µm | 0,5 | |||||

| Working temperature | °C | 10 – 35 | |||||

| T-ALL SERIE P | 3 | 6 | 10 | |

|---|---|---|---|---|

| Max Permissible Error | µm | 1 µm + L /500 | ||

| Repeatability | µm | 0,5< | ||

| Resolution | µm | 0,1 | ||

| Working temperature | °C | 20 ± 1 | ||